BOPP Lamination Plant and BOPP Woven Bag Manufacture: The Future of Packaging

BOPP lamination plant and BOPP woven bag manufacture are becoming increasingly popular in the packaging industry. BOPP, or biaxially oriented polypropylene, is a type of thermoplastic that is used to make packaging materials. It is a popular choice because of its excellent properties such as high strength, flexibility, and durability.

In recent years, the demand for BOPP lamination plant and BOPP woven bags has grown due to the rising demand for packaging solutions. BOPP woven bags are widely used in industries such as agriculture, food, and construction. These bags are preferred over other materials as they are lightweight, strong, and cost-effective.

The BOPP lamination plant is used to laminate BOPP film onto various substrates such as paper, woven fabric, and non-woven fabric. The process involves applying an adhesive coating onto the substrate and then laminating it with the BOPP film. The end product is a laminated material that is water-resistant, tear-resistant, and has a glossy finish.

The BOPP lamination plant is designed to cater to the needs of different industries such as packaging, textiles, and printing. The plant can be customized as per the requirements of the customer. The BOPP lamination plant can be of different types such as solvent-based, water-based, and extrusion-based.

The BOPP woven bag manufacture is a process that involves weaving the BOPP fabric into bags for various applications. BOPP woven bags are extensively used in the agriculture industry for packaging products such as grains, seeds, and fertilizers. These bags are also used in the construction industry for storing and transporting cement.

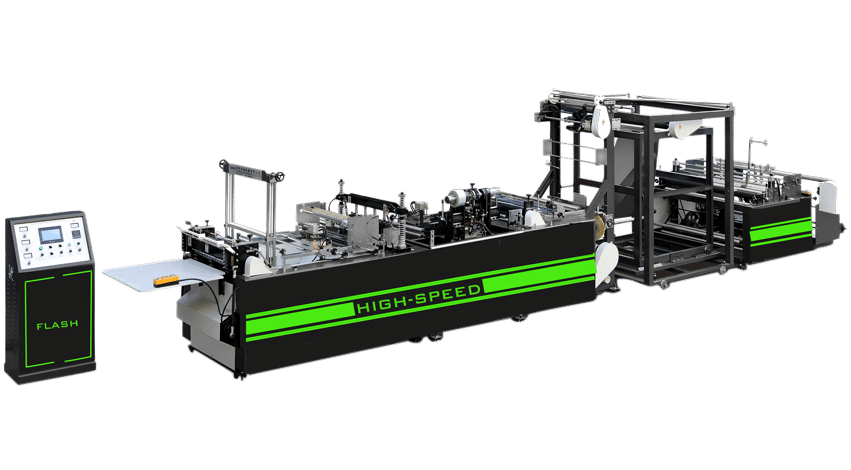

The BOPP woven bag manufacture process involves weaving the BOPP fabric using a circular loom machine. The bags can be printed with company logos and product information using a flexographic printing machine. BOPP woven bags are available in different sizes and can be customized as per the requirement of the customer.

The BOPP woven bag manufacture and BOPP lamination plant are essential components of the packaging industry. These processes enable the production of high-quality packaging materials that cater to the needs of various industries. The demand for BOPP woven bags and BOPP laminated materials is expected to grow in the coming years due to the increasing demand for packaging solutions.

In conclusion, BOPP woven bag manufacture and BOPP lamination plant are important processes for the packaging industry. These processes enable the production of quality packaging materials that are used in various industries. The demand for BOPP woven bags and BOPP laminated materials is expected to grow as packaging solutions continue to evolve.